Expanded Polystyrene is widely used to package fresh fish and produce, as it is able to help keep food fresh through the distribution chain. It is also used within the pharmaceutical industry to package items that are temperature sensitive and need to be transported throughout the world.

Expanded Polystyrene has many useful properties. It has low thermal conductivity, and therefore can be used as an insulator against heat and cold. With its high energy absorbing properties, EPS is excellent at absorbing shocks, and protecting delicate items. EPS has no loss of strength in damp conditions, so it is ideal for cool-chain products. Being moisture resistant, EPS easily meets the most stringent of hygiene requirements.

Made up of 98% air,

Expanded Polystyrene is extremely lightweight, and as a result, the cost of transport of this material is significantly reduced. This in turn reduces emissions due to reduced fuel consumption, creating less impact on global warming. Further,

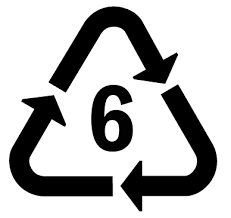

Expanded Polystyrene is odourless and non-toxic. It does not, nor has ever, emitted chlorofluorocarbons (CFCs), and it is recyclable. The uses for EPS are almost limitless. It can be moulded into many shapes or forms to meet the customer’s and their product’s protection and insulation needs.

Expanded Polystyrene is a closed cell, thermoplastic, lightweight, rigid cellular plastic material. It comes as small beads of resin. The beads are impregnated with pentane, a naturally occurring gas. The beads are then heated in a pre-expander. The combination of this heat and the rapid release of the gas, the bead is expanded to almost 50 times its original size.

After expansion, the beads are aged between 12 and 48 hours, which allows the internal vacuum in the beads to refill with air. The pre-expanded EPS beads are then injected into a steam chest mould. Steam applies heat and pressure, which fuses the beads together into the required shape or form.

For further information on this product, or to find out which material will best suit your application, please contact us..

.png)